In a previous life, I worked for a car manufacturer – a market leader at the time. We were doing pretty well, winning multiple awards in our category for top car, car of the year, and so on.

But something was bugging me.

Although we were winning awards for the models that got to market, a lot of them wouldn’t even get to that point (or would fail once they did). Our process took a long time and felt reactive and inefficient. Every time we would develop a new model, we’d start from scratch.

Everything would seem fine and then problems would come up right before the deadline that we’d have to react to and fix in panic mode.

Relatable?

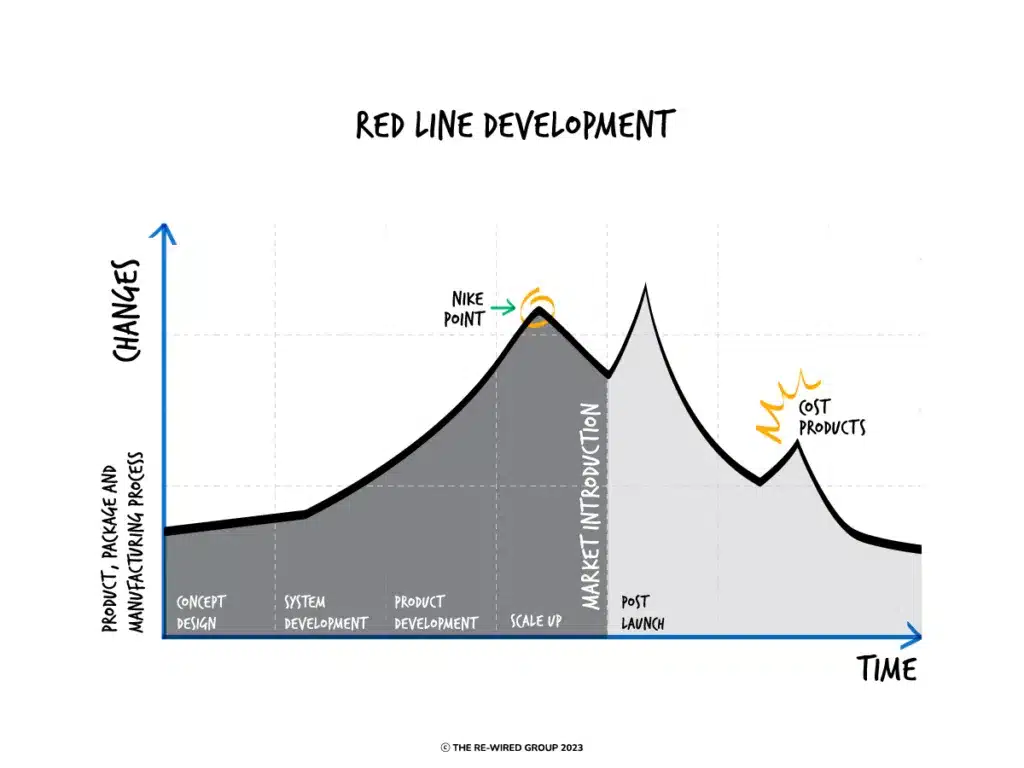

We were on what I call the “red line” of development.

Red line development is a linear and inherently reactive process. Instead of anticipating problems early and working to head them off, teams wait for problems to occur and then react. Conflicts and issues arise later when the costs of making changes are much higher. This increases the failure rate of new products – and can be incredibly frustrating for teams.

I’m sure a lot of you can relate to this.

We are often approached by product leaders and VPs who have experienced multiple product failures. Their teams are in that red line of development. They’re stuck solving problems all the time – problems they created themselves by reacting, overengineering, and not talking to one another.

Did you know that nearly half of all resources on new product development and commercialization are spent on projects and products that either get canceled or underperform?

The numbers vary but the conclusion is the same: between outright failure and poor performance, most companies are spending a lot of money on product development and not getting much return.

Knowing this, you can decide that product development is just a crapshoot. It’s that way for everybody, so it must just be the way things are. Lots of people and companies do just that.

An alternative way to build products

The alternative is to look for ways to do it better and help your team and your company stand out from the pack. That’s what we did with the auto manufacturer.

We reinvested some of the revenue from successful product lines back into the business. We began searching for new and better ways to do things, in particular within product development.

At the time, there was one competitor in a different part of the world that was developing new models and cars way faster than us – and frankly, anyone else in the market. They were able to develop products that customers liked and seemed to get through the process without too much drama. And they were much more profitable.

I couldn’t help but be curious about what they were doing different from us. So a colleague and I went to study them.

And what we found was game-changing.

At first, their approach didn’t look that different compared to ours. Then I mapped both on a graph depicting the number of product, process, and package changes and their cost over time. I also put a marker indicating the point of launch.

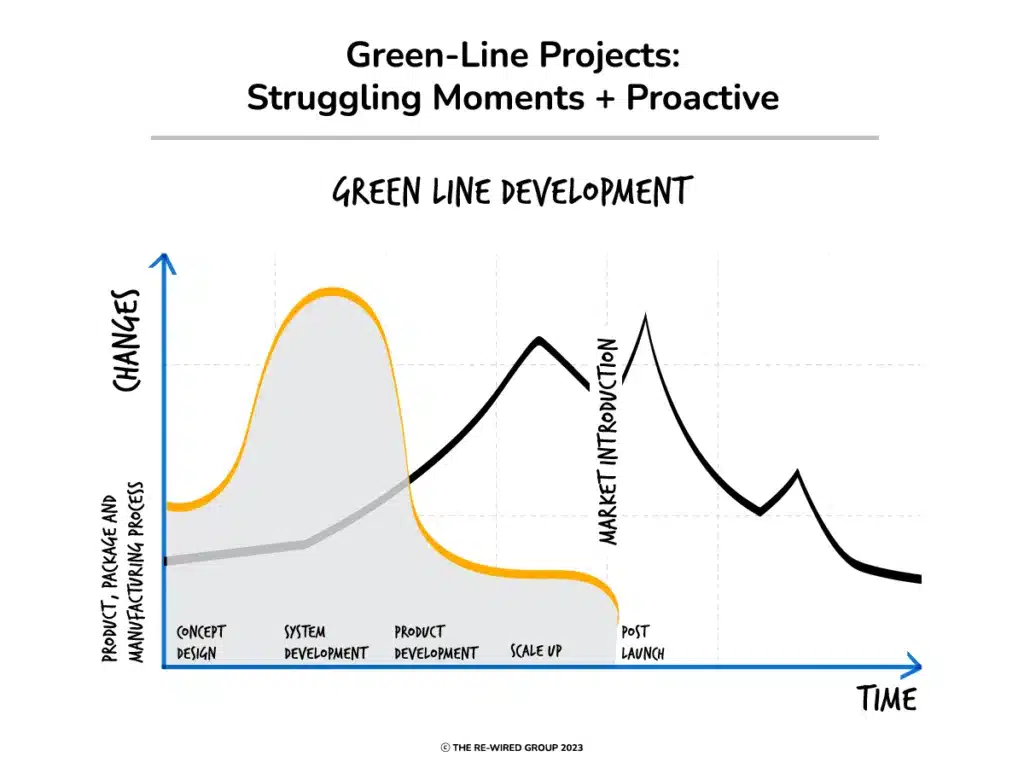

Their curve looked nothing like ours. They were on what I call the Green Line of development.

What is Green Line development and how does it relate to product development?

Green Line development is an umbrella term for a set of tools and methodologies that are proactive and anticipatory in nature. When fully leveraged, these methods result in better products and higher success rates.

Green Line development focuses on building up organizational knowledge and on allowing teams to refine how they work together so they don’t have to start from scratch every time.

It works on the recognition that:

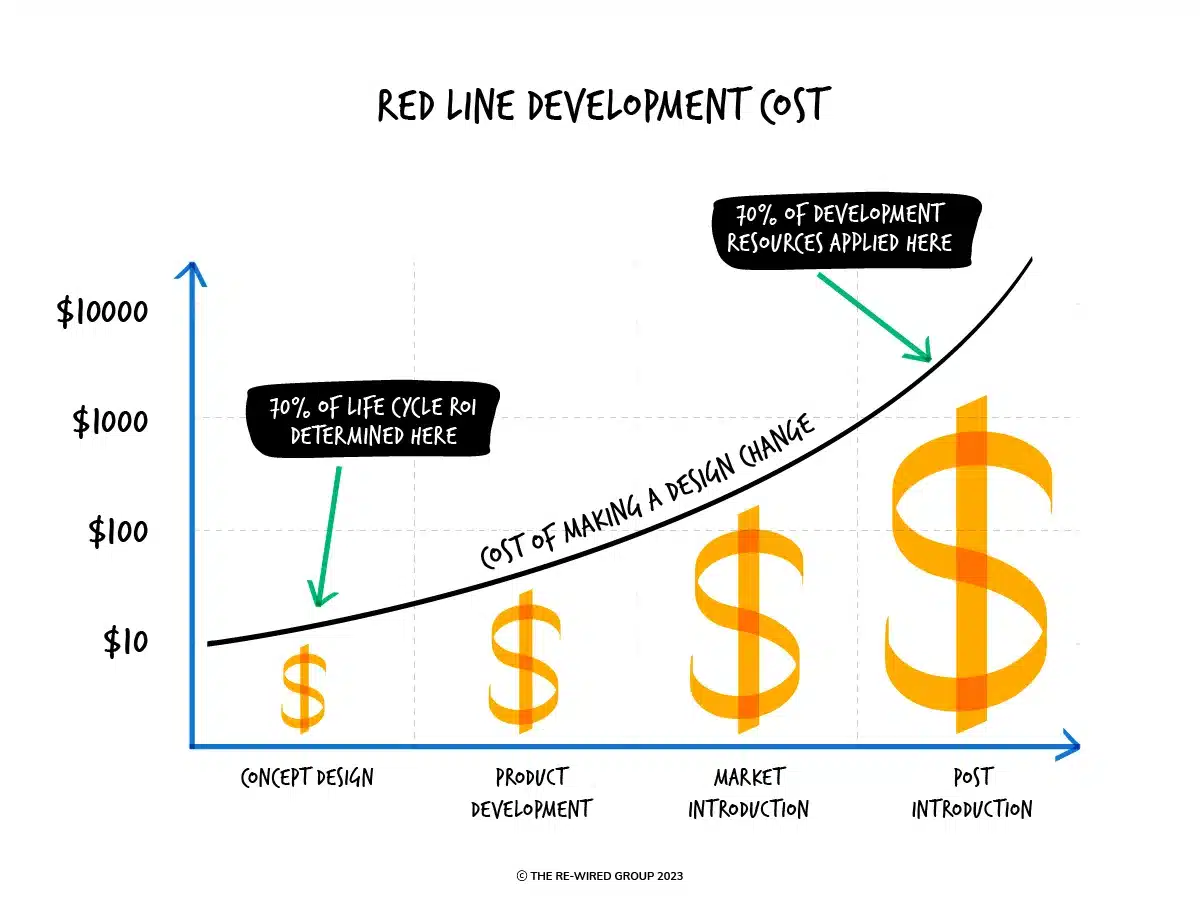

- 80% of a product’s life-cycle costs are fixed by the decisions made within the first 10% of the project.

- The costs of reacting (e.g., redesigning products, changing suppliers, etc.) escalate in an exponential way as the work advances into later phases of development.

It’s a way of thinking about product development that is front-loaded with resources. A huge amount of validation and prototyping happens in parallel in the beginning. Teams are spending time to understand the links in the chain – and to make touchpoints and interconnections work smoothly.

With Green Line, there are still many changes to the product but the vast majority are happening earlier in the development cycle (hence the initial jump in the curve).

Changes at this stage are a lot easier and cheaper to fix compared to changes on the red line that shoot up near to and post-launch.

It’s all about the quality of the process, high teamwork, and communication. Each team talks to the other teams up or down from them to understand how it all fits together, and how the entire system is supposed to work.

It’s the polar opposite of the linear development we see in the red line. In a red line approach, teams only work on their bits and wait for problems to occur before fixing them. This introduces costly delays and drama – because a problem in one area can easily undo work that’s already being done in another area, creating problems down the line like a domino effect.

Key differences between red line and green line development

Launch and mindset

Teams that use red line development see the launch date as the deadline by which they need to have something to ship. Their focus is on making it work once; they can worry about fixing it later. Their goal is to build all the components and test them – often in an isolated and disjointed fashion.

Because they’re aiming to make it work once, they’re losing sight of how the entire system works together. And it’s not just on the technical level, but contextually on the overall process level. They’re racing to the deadline, not really understanding their purpose or what they’re trying to do for the customer.

Green Line starts at the same place of not really knowing what they’re building.

But the mindset of the team is different.

They see the launch as the date by which they have to have understood how everything works together as one. How all the pieces integrate and work together. They’re aligning their understanding of what the customer’s desired outcome is. Rather than make the product work once, they’re making the process work as many times as possible.

Causality

To illustrate, let’s go back to the car manufacturing scenario. When we were on the red line, we’d start from scratch every time a new car had to be built. The exhaust person never talked to the transmission person. The transmission person never talked to the engine people.

So when we put it all together at the end, something wouldn’t work – but we would have no idea what and why.

So we’d spend a ton of time diagnosing and trying to replicate the issue so we could fix it. As different units, we had no knowledge of the other team’s work or the point of integration.

Had we adopted a Green Line approach that makes it easier to find causes, we would have been able to pinpoint the issue right away – and fix it without too much hassle before handing it off to the next team.

When embraced fully, Green Line tools and methods have the power to maximize product value for both the customer and the company.

Prototyping

When on the green line, we’re prototyping to learn. The focus is on keeping institutional knowledge alive and documenting the process for the next team that takes this up.

We’re learning what makes it work but also what makes it break. And the attitude is that it has to work as many times before launch – it has to be right the first time.

We’re prototyping vigorously, so that by the deadline, we can be done with all discoveries, know how the system works, and be sure there are no bugs to go back and fix.

Methods and tools of the Green Line development philosophy

- Jobs to be Done (JTBD)

A core part of Green Line development is Jobs to be Done (JTBD).

In a recent blog, we looked at some of the reasons products fail. One of the keys is that organizations don’t take their customers’ needs into account.

Some of these failures come from a lack of empathy from the decision-makers in the organization who are not taking the necessary time to study and understand the customers’ true needs.

In Green Line development, JTBD takes care of this by ruthlessly unpacking customer insights and the meaning behind words. It sets the scene for robust design of products, anchored in real customer behavior, not claimed.

- Strategic Clarity

Strategic clarity helps with knowing the overall strategy for the company’s portfolio and how this project fits into it.

- Forces Of Progress

This is the understanding that in situations where we want to make progress or solve a problem, there are forces that move us toward that progress and forces that hold us back from making that progress. Outlining these helps us be more intentional about making changes to product, marketing, or sales processes.

- Systems Thinking

A way to view the product as a system in and of itself and as part of super & sub-systems.

- Robust Design Of Experiments (RDOE)

Allows us to produce better prototypes that enable us to learn more about our product performance, function, etc. faster and ultimately cheaper.

Following Green Line product development is far better for your organization and customers

One customer we worked with was a Canadian business delivering fresh baked goods. Many of their new products were failing so they asked us to apply Green Line principles to their stores and business. We helped them cut their capital spend from $18 million to $2 million while growing margins by 30% and increasing sales by 20%.

Using the Green Line development method helps you anticipate problems earlier on in the development process. Why? It can help cut development time and cost by 50%, not to mention increase top-line sales by 20%.

Bob Moesta

Results like that are clearly good from a corporate perspective. But what about the development teams?

The response from developers at client companies speaks for itself. They’ve said that Green Line development has taken them from not understanding the formula and the customer (complete red-line) to “being able to field the lowest cost most consumer-relevant product lines”.

If you’re looking for a product development process that’s more likely to be profitable, more likely to succeed with customers, and less likely to be drama-strewn, you need to stay on the Green Line.

And if you get stuck, give us a shout – we apply a lot of this in our product development consulting.

Using the Green Line collection of methods and tools will help you proactively prepare for successful product launches, and understand the “why” of customers, all while increasing your effectiveness as a business. Win-win-win.