The Five Bedrock Skills of Innovators and Entrepreneurs

Throughout my more-than-thirty-year career developing and launching over thirty-five hundred products and services, I’ve come across thousands of other innovators and entrepreneurs.

One day, I intentionally took a step back and asked myself, What do my mentors and successful entrepreneurs think or do differently from others? What skills do they possess?

Upon reflection, I narrowed it down to five subtle skills that set them apart.

These are the hidden parts of innovation that nobody seems to teach in an in-depth way—the stuff in between innovation tools and processes. I believe that they are the things that differentiate successful innovators and entrepreneurs I’ve met along the way from being typical engineers, software developers, or CEOs.

- Empathetic Perspective: people with this skill can detach from their own perspective and see the subtle differences between the many different perspectives surrounding their thing—internally and externally.

- Uncovering Demand: people with this skill can detach from their product or service and look at the demand-side of the equation—seeing struggles, context, and outcomes.

- Causal Structures: people with this skill have a dominant view of how the world works based in cause and effect.

- Prototyping to Learn: people with this skill know that they do not have all the answers and run tests to get empirical data to discover and build new theory instead of relying on existing theory and testing hypotheses.

- Making Tradeoffs: people with this skill understand that they cannot do everything and are skilled at making essential tradeoffs to launch a product that is not perfect.

By calling out these five skills, I want to impart the importance of the role that they play; it’s the rigor and depth behind them that I wish to convey. Most people perform these five skills too shallowly. And those who do understand the importance of their depth didn’t acquire that knowledge in a classroom or a book. They did so through life experiences. My hope is to pave an easier path for you by making them explicit and giving you a way to see and practice them.

I also want to pay homage to my key mentors Taguchi, Deming, and Moore, as well as another great, Clay Christiansen of the Harvard Business School, with whom I architected a theory called “Jobs to Be Done” (JTBD).

It’s the notion that people don’t buy products; they hire them to make progress in their life. It gets to the root of supply versus demand.

All four of these innovation giants shaped me. I was a receptacle for their knowledge; it became a part of me, and I want to pass their wisdom along to whomever wants to listen.

The Learning to Build book isn’t a roadmap that will dictate the only true way to innovate; it’s about putting more arrows in your quiver rather than debating the “best” way to innovate. It’s simply a collection of the lessons and tools that I learned along the way, the things that helped me make progress.

In reality, there might be a hundred different ways to effectively innovate, and it depends on your context. It’s up to you to decide which elements to pick and choose. And like anything else, I expect the wisdom shared will someday become obsolete.

But everything new is built on the old, so I felt it was my responsibility to share with you what was shared with me in hopes of advancing the innovations of tomorrow.

Are You Struggling to Innovate?

Does this sound familiar?

- Are you always one prototype away from a solution but never seem to get there?

- Do you spend most of your time fixing problems that you did not anticipate?

- Does it seem like everything is going well right up until launch when it all falls apart?

- Are you getting very little return on the resources you deploy?

- Does the performance of your product in the market rarely meet the predicted targets?

If you answered yes, let me teach you both the science and art to innovation.

My hope for you is once you pull together the fundamental pieces, it will spin you up in a way that allows you to see the world nobody else can see—The Matrix—and building will become your superpower too.

What’s an Innovator?

I know you want to dive right into the five skills of innovators and entrepreneurs, but first we need to gain a little more perspective and build some common ground on how new products are created.

To do that, let’s journey back in time…

By 1988, now a graduate, I found myself working full-time at the car manufacturer, still under the direction of Taguchi, Deming, and Moore. Despite the establishment of many better problem-solving techniques, we still weren’t keeping up with our Japanese competition and neither were our American counterparts. In Japan, industry leaders were creating new cars in half the time—three years from conception to release, compared to our six—and they were also doing this at half the cost, which was kind of amazing.

If we wanted to stay competitive in the industry, we’d need to make drastic changes, and fast. That’s when Deming, a team of executives, and myself went to Japan on a study mission.

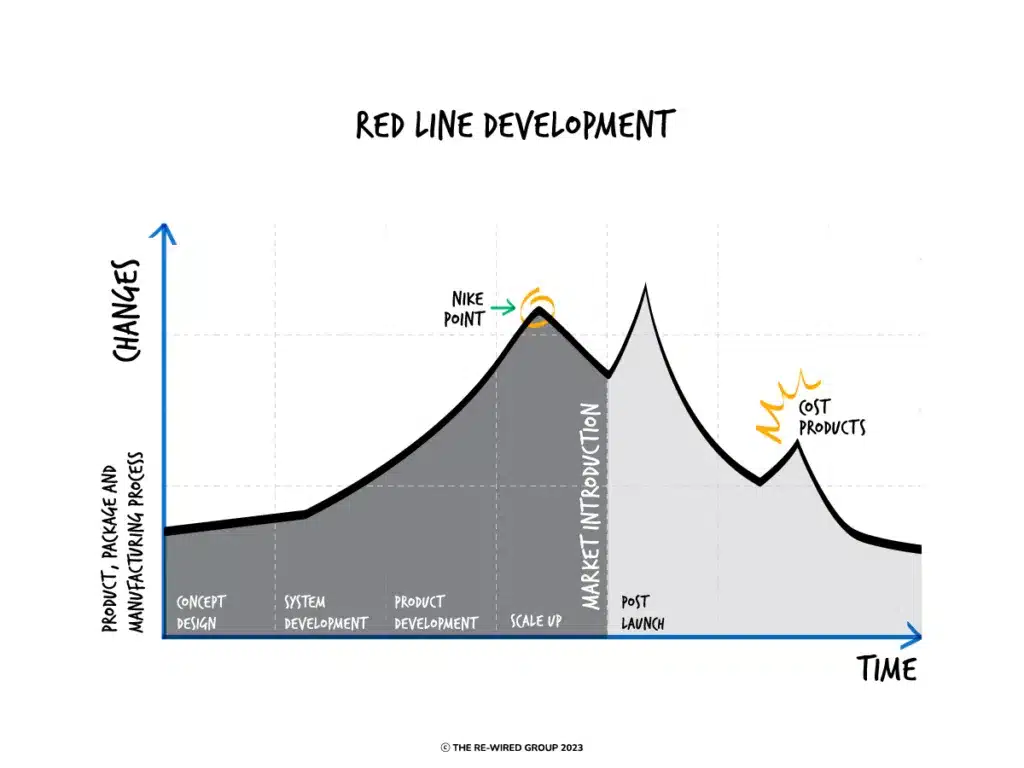

After a careful analysis, we noticed significant differences between our development process and our Japanese counterparts. We came to refer to this as “red line” versus “green line” development.

Let’s contrast the two approaches.

On the red line, our process started with an early concept design that was readily accepted. The design would be committed to paper, where we would spell out the details—engine, transmission, body, etc. At this early stage, we’d make only slight modifications. Then each team would break off into their individual silos and begin working on their element.

The engine designer would make the best engine, the transmission designer built the ideal transmission, and so on. Agreement and common understanding were assumed, and the early process would run relatively smoothly—changes were in the thousands.

But as we got closer and closer to launch, design changes would skyrocket—by almost one hundred times. Our teams worked in silos that were extremely independent, so they never consulted one another in an in-depth or meaningful fashion as they built out their components.

As a result, when we got close to launch and finally started to pull everything together, there would be problems; the car would not connect perfectly. For instance, we’d put the transmission and the engine together, then something would break.

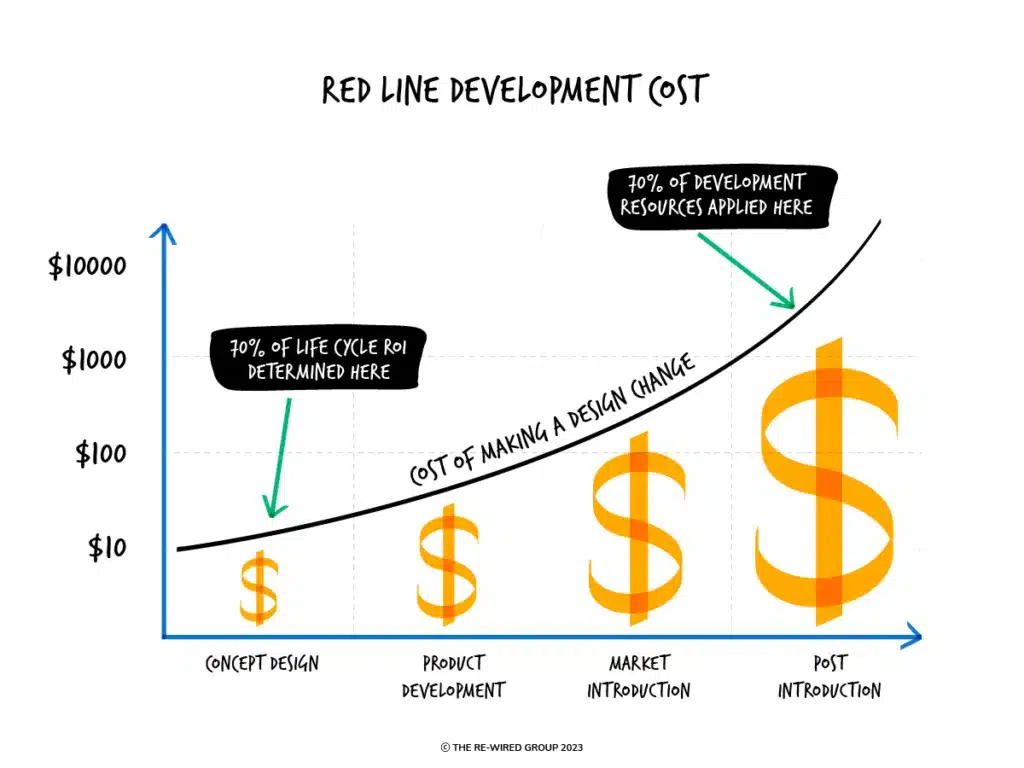

From a cost perspective, discovering these conflicts and differences late is disastrous. Now it would take a massive effort and significant time and money to fix them. At the beginning of the design, changes are negligible; it’s on paper only. On the backend, however, changes run in the millions. There are custom steel tools that now must be replaced, costing in the millions each. Plus, each change impacts another element, which then must also be adjusted.

It felt like a high-stakes game of whack-a-mole, with a very real, looming deadline just around the corner. In the end, we would have to freeze the design and launch the car, then go back and patch up problems after launch—like the rearview mirror. The red line was a very reactive process!

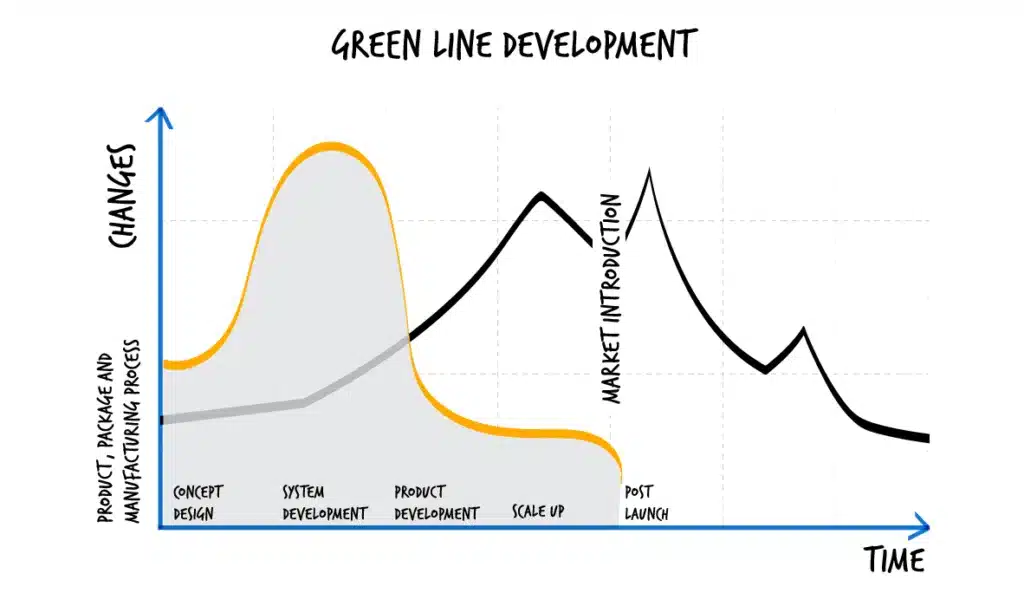

When I laid out the graph of changes over time for our green line competition, I saw something quite different…

For starters, the Japanese manufacturer did not start with one readily accepted concept design. Instead, they had multiple prototypes and made tons of changes in the early stages when the design was still on paper—one hundred times the prototypes.

Then when they eventually broke off into their individual silos, there was a lot of communication to ensure their components worked together and that they understood each other’s perspectives. Nothing was assumed. In essence, they pushed their product to fail early in the process, before they ever pulled the entire design together, dramatically reducing time and money spent.

In the end, the Japanese manufacturer got to the finish line with a lot less drama. And oh, by the way, their cars actually performed better in the marketplace too. We needed to change our approach.

A Different Way to Innovate

As a young engineer, I was beginning to realize that there was a behavioral side to successful innovation. It wasn’t enough to simply know how to build; the approach to the process mattered too.

On the red line, our process was very prescribed, standardized; it removed thinking. We simply followed the process—it worked (or so we thought)—think “best practices.” But we were planning (or guessing) when we were the stupidest; I call this simplicity on the wrong side of complexity. It’s easy to develop the best engine if you don’t need to consider the transmission. We only planned what we knew and never anticipated the unknowns or discovered tasks along the way.

The green line developers approached their process from a different perspective. They took a step back and viewed the whole, which caused them to do the right things at the right time. Rather than using their process to remove thinking, their process created the space for deeper thinking, collaboration, and continuous improvement.

They not only made things work but also knew where they broke; their focus was on parallel development (versus serial), which caused them to use prototyping in a very different way. As a result, they had a deeper understanding of the customer that went beyond the customer’s voice and what they stated to a place where they understood intent.

We used pictures, while they used movies; we saw problems, whereas they saw systems; we watched and waited while they made it fail early and often to learn. In essence, we were arrogant, and they were humble. I found that overall, their approach was way more about mindset than just process.

This isn’t just the story of two commercial car companies. It’s the story of two development teams and their approach to the process of creating new things.

Throughout my career I’ve found that most organizations create new products on the red line. What kind of company are you? Young Bob was a red line innovator, but I’ve evolved and so can you.

Through tens of thousands of hours of practice, and through interactions with some of the most influential innovators in the world, I’ve reflected on my experience with them and boiled down the difference between red line innovation and green line innovation into the five skills of innovators and entrepreneurs.

They are the unwritten skills that I’ve developed over the years after first trying, failing, learning, and finally succeeding. Throughout the upcoming chapters, I will teach you how to build these critical skills, but first, let’s take a brief look.

What are the five skills of innovators and entrepreneurs?

Empathetic Perspective

When you’re on the red line, your own perspective is the most important one. If I’m the engine guy, I need to make sure that I explain my perspective to the person building the transmission, but I’m less sensitive to their perspective. I don’t truly consider the transmission designer’s point of view when building my design. I may imagine what they think, but that’s vastly different than knowing; it’s very superficial.

Whereas on the green line, I see the situation from multiple perspectives: the customer buying the product, the designer developing the transmission, the people on the assembly line, etc. I get out of the conference room or the engine lab and seek out their perspective. I walk the assembly line, I talk to the transmission designer, and I utterly understand the many perspectives that could impact my system. Then when I go back to build, I do so with that in mind so that I can see the conflicts before they arise.

Uncovering Demand

When I was young and developing products on the red line, I was told to “build it, and people will come.” Demand on the red line was the number of “people” in a certain age group and demographic set; I could have everybody. The target market was an amazingly simple notion—who. It was attributes and correlative demographics in a very superficial way.

But what causes someone to buy? The fact that I’m fifty-five, live in this zip code, and have that income does not cause me to buy the New York Times. Something happened that caused me to say, “Today’s the day that I’m going to subscribe to the New York Times.” What?

Green line innovators understand what causes people to buy or to change behavior. Specific things had to happen in my life before I said, “Today’s the day…” Value is in the eye of the buyer, and uncovering demand is about understanding where your buyer’s value is created.

And to be clear, profit is not value; creating value for the company is different than creating value for the customer. Ultimately, uncovering demand is about broadening your worldview and realizing that innovation is about helping people. It’s not about you or your product’s features and benefits; it’s about who, when, where, and why. This is the key to defining demand.

Causal Structures

On the red line, people tend to focus on problems and solutions. It’s very reactionary. They wait for a problem to arise, then react. They focus myopically on one aspect or feature but fail to see the whole. People on the red line chase their tails like young Bob with the rearview mirror. Every solution creates another problem, and they are always one problem away from the answer, yet they never get any closer to a solution.

Whereas on the green line, people see the big picture and understand how the entire system works. People who are good at causal structures understand that a problem is a derivative of functions and variations of functions within a system. They are curious and develop a deep understanding of how things work—a broad, big picture view as opposed to a myopic, singularly focused view.

There are always two sides to every problem. People good at causal structures take a step back and see the whole.

Prototyping to Learn

On the red line, people do a lot of A/B testing. This is a direct result of looking at the world through the “problem space” as opposed to the “function space.” Because they think in terms of one problem and one solution, they go looking for answers like a needle in a haystack. What’s the one thing that will solve our problem? It’s the notion of testing one factor at a time. Results on the red line are not typically reproducible because they are isolated, aimed at finding the “one” root cause that made the problem.

Whereas on the green line, because they are in the “function space,” they design experiments that change many variables at once to learn how the system works, assuming nothing. They are prototyping to understand the possible ways it can fail. Constantly asking, “What are the failure modes?” This understanding allows them to reduce costs while solving problems because they can see the whole. They find the “root causes”—the sets of things that work together to make the system work.

On the green line, you’re focused on learning. Whereas on the red line, you are testing to prove a hypothesis, to verify, and then when it doesn’t work you point fingers at everyone else.

Making Tradeoffs

On the red line, people are not taking the time to see tradeoffs. Let’s say for instance that you are creating a mobile app of a desktop application. If you try to do everything on the mobile app that’s available on the desktop, the system will run slow. You can have it all, but you will lose functionality, or you can strip it back to only the pieces that people would use a mobile app for. It’ll be faster but not fully functional.

On the red line, people are focused on making everything perfect, so they do not see the big picture and therefore can’t make tradeoffs. They usually end up way over budget only to find that their product isn’t that well received in the marketplace. Whereas on the green line, they can see the whole and understand where to make explicit tradeoffs. They have an eye on cost and demand, so the tradeoffs are easy.

You can probably already identify areas of strengths and weaknesses after those brief descriptions.

Applying the Five Skills of an Innovator

At this point, you may have an inkling of where you’re already succeeding or failing with the five skills.

Here’s a set of questions to ask yourself:

- Empathetic Perspective: Do I deeply understand other people’s perspectives—external customers and vendors, as well as internal designers and assembly line workers? Do I get where they are coming from? Can I play it all out through time?

- Uncovering Demand: Do I understand what causes demand for my product? What dominoes must fall before someone says, “Today’s the day…” What causes someone to fire another product and hire mine?

- Causal Structures: Am I curious? Do I constantly want to figure out how things work, even when they’re illogical or irrational? Do I believe in randomness? (Randomness is the opposite of causal structures.) Do I take the time to frame questions before building my prototypes?

- Prototyping to Learn: Am I building sets of prototypes, as opposed to prototyping two aspects at a time, A/B testing? Am I causing things to fail or waiting for them to fail and reacting?

- Making Tradeoffs: Am I striving for perfection, or can I see the whole and understand that I can’t have everything? Do I understand how to frame my tradeoffs from both the supply-side and the demand-side? Do I err on the side of the customer or the company?

The book, Learning to Build, continues to delve deeply into each of the five skills of innovators and entrepreneurs and offer tools and techniques for you to practice in your own life.

If you’ve read my book Demand-Side Sales 101, which was written and framed around how people buy, you will see some similarities, especially as it relates to empathetic perspective and uncovering demand. It’s true there are similarities, but there are also subtle differences.

Ultimately, this book is about learning to manage and create things as opposed to just helping people buy, and as you will see, when the context changes, so does the meaning behind the tools.

Summary

Learning to Build is the red pill of innovation, and once you’ve consumed it, you won’t look at innovation and entrepreneurship the same.

You’re like me—prone to overthinking—I’m sorry. But I believe that the world would be better off if more of us overthought life. Imagine the impact on society as a whole. Hopefully, I’ve inspired you to take the five skills to the next level.

I’ve categorized the reasons that people would hire this book into four JTBD categories:

- Help me extend myself so I can better myself.

I am a lifelong learner. Reading this book was more of a personal quest to better myself and learn new skills. While I’m interested, I don’t need to apply this material in an accountable way. It’s similar to a hobby, like gardening or learning to play chess. Progress for this “job” is about ongoing, continuous self-improvement. - Help me take a deep dive into areas where I’m lacking so that I can improve the way I design and innovate.

I’m a builder/creator of things. Reading this book opened my eyes to my strengths and weaknesses. I can see now where I excel and where I need to improve to take my innovations to the next level. There’s work that I need to do, but I’m approaching it as an individual. - Help me add these skills to my organization so that my teams can successfully innovate.

I run an organization. Reading this book showed me that as an organization, we need to work on developing these skills. We have the tools and the processes to innovate, but we are missing the ingredients in between; I can see that we are not clicking on all cylinders. - Help me learn these skills so that I can run my small business more successfully.

We are not in the business of innovation, but reading this book showed me that learning to flex these innovation muscles could help me respond better to changing markets and help me advance my small business.

Sound familiar? I recommend you get a hold of the book.